Open & Closed Die Forgings

- Highest reliability

We are your partner when high mechanical stress has to be taken into account and the highest reliability under aggressive environmental or ambient conditions is required.

- Production from one source

From steel production to the completion of the forged product, we carry out every step in the production process. We take responsibility ourselves and ensure that our customers receive consistent quality assurance. We check and document the quality of our products at every point of the production chain.

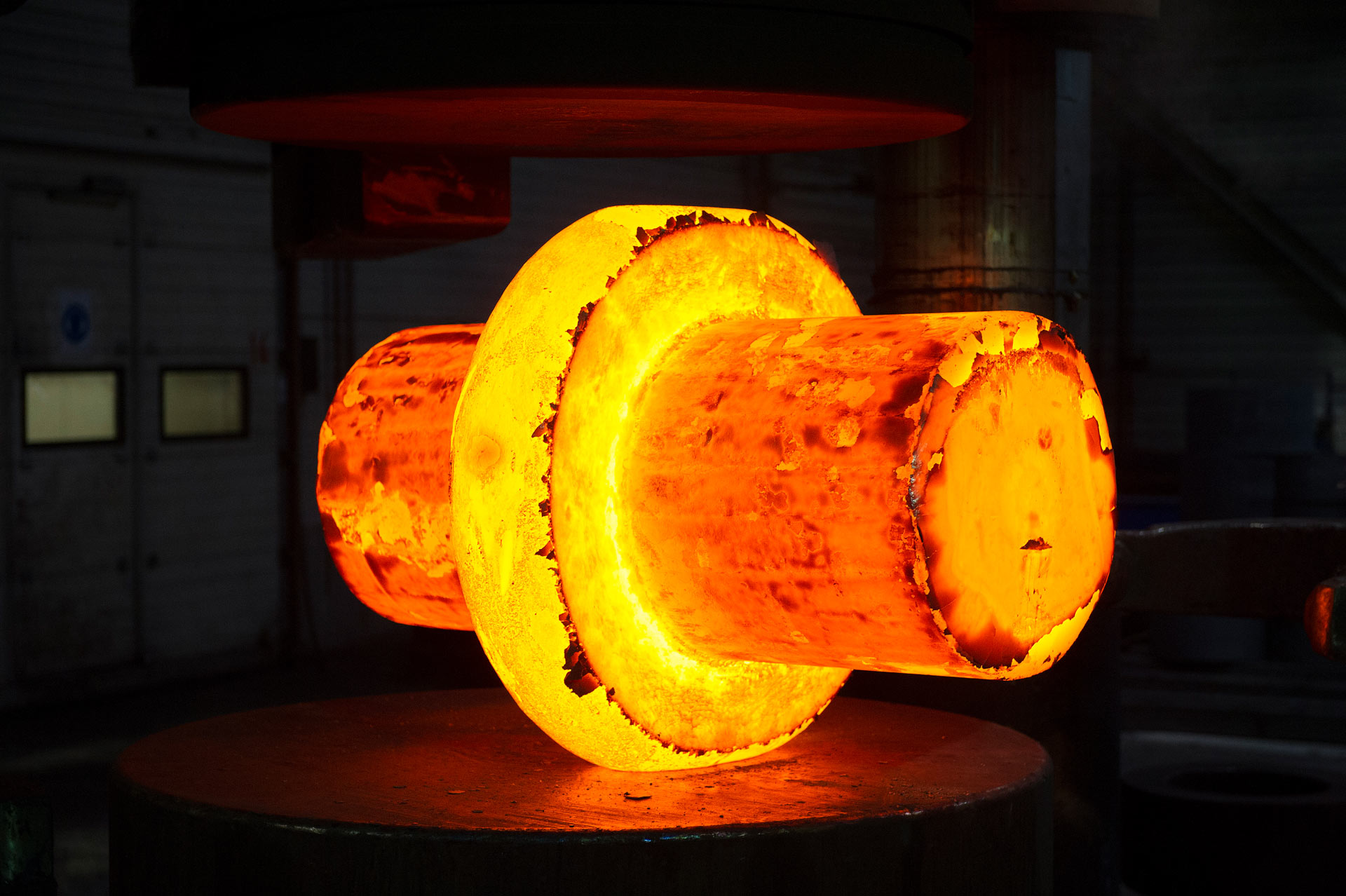

Open die forgings

Our open-die forgings are characterised by the tightest tolerances and large dimensions. In our ultra-modern facilities, we manufacture forgings to drawing with a weight of up to 35 tons. We have many areas of expertise, including the production of impellers, shafts and discs, for compressors or turbines and components for fasteners, separators, pumps and valves in a pre-machined condition.

Closed die forgings

Precision and resilience, as required for drill teeth, shrouds or mandrels, for example, are the hallmarks of our drop forgings. The products that we develop together with our customers have proven themselves under the toughest operating conditions and enjoy an excellent reputation worldwide.

Holland Dredging Industries™ has over the years been supplying critical forged components for the Dredging, Mining and Metal industry succesfully.